THE CHALLENGE

Currently, 3D printing is limited to the applications of available materials, which are not able to withstand high temperatures. Therefore, there is a need for a high temperature build environment for 3D printing that allows for the use of high performance and application specific polymers.

OUR SOLUTION

Researchers at Virginia Tech have developed a novel desktop-scaled Fused Filament Fabrication additive manufacturing system capable of processing high performance polymers at a low cost. The desktop printer presents a controlled high temperature build environment suitable for materials such as PPSF, ULTEM, and polycarbonate.

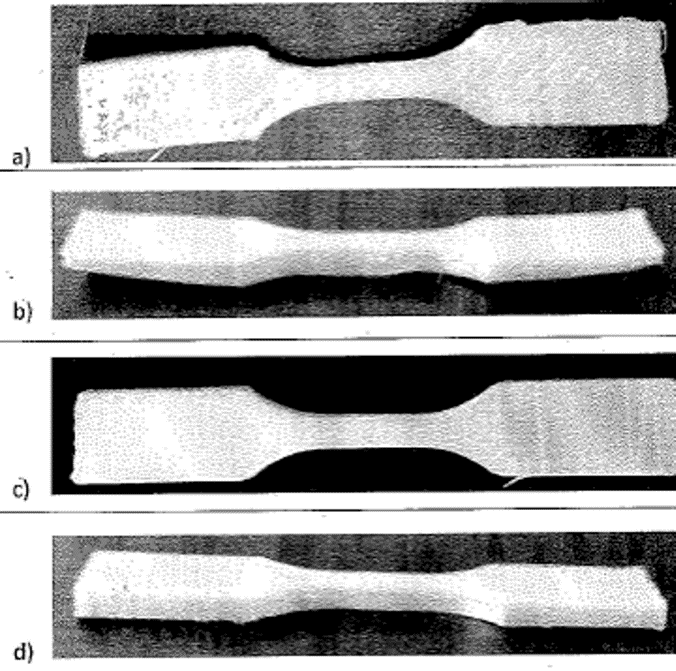

Furthermore, the printer enables for high quality prints by reducing warpage and improving inter and intra layer adhesion. With these capabilities, the invention takes 3D desktop printing to new areas of application such as the aerospace and automotive industries, while still maintaining the printer’s scale/ cost/ democratization.

Figure: Tensile bars printed at low temperature (a and b) and high temperature (c and d)

Advantages:

- Can provide build environment of up to 400°C

- Isolated electronics reduce printer cost

- Limited maintenance