THE CHALLENGE

3D printing has emerged as a promising alternative to traditional manufacturing methods. Of the multiple 3D printing strategies available, the FDM build method is the most widely used in both commercial and home use applications. The FDM method uses a heated nozzle to melt a polymer filament and apply the material in layers to build the desired structure. This method is simple and reliable, but the layer by layer construction results in a model that shears easily under pressure making this method a poor choice if printing objects that will be subject to physical stresses.

OUR SOLUTION

Inspired by the structure of sea shells, Brook Kennedy and Edward Coe have developed a new method of corrugating material deposition layers in FDM 3D prints for additional strength. Corrugated building materials are relatively common— corrugated metal roofing panels and corrugated packaging cardboard is ubiquitous—but applying the idea to material deposition in a 3D print is much newer. The Virginia Tech team devised two methods of achieving the corrugations that give their FDM prints the ability to resist delamination damage due to shear forces. The first strategy involves a series of transitional layers that gradually build up the corrugations from the initial planar layer. The second relies on discontinuous planar transition layers that form the base for the corrugations. This new method of applying layers while producing FDM prints will vastly improve the mechanical strength and reliability of printed parts in plastic at a product scale and in concrete at a building scale to resist shear forces in seismic regions.

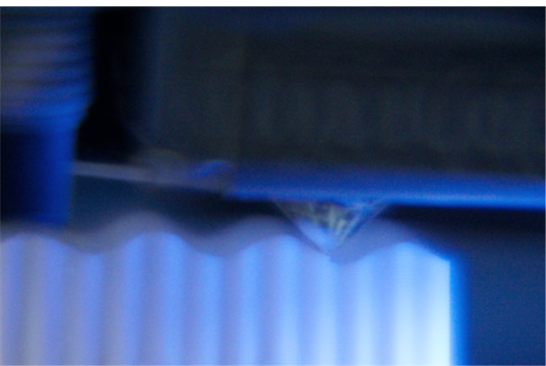

Figure: Nozzle of an FDM printer applying corrugated layers in a print.