THE CHALLENGE

Water treatment of large volumes of liquids is a critical aspect of many industrial processes, notably in the chemical, food, and pharmaceutical industries. With energy costs rapidly rising, it is highly desirable to improve the treatment efficiencies and adaptiveness with lower energy consumption.

OUR SOLUTION

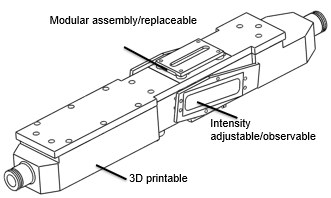

Hydrodynamic cavitation (HC) is an energy and chemical saving water treatment technology that involves vaporization, bubble generation, and bubble implosion. The Coutier-Delgosha lab at Virginia Tech has developed a multifunctional HC device adaptive in various industrial scenarios, such as sterilization, degradation for antibiotics and other organic pollutants. The device can be 3D printed with modular-type replacements, allowing for lower manufacturing and maintenance costs. In addition to the cavitation device itself, the team has developed an operating system and methods to adjust cavitation intensity, thus optimizing the treatment efficiency, shortening working time, and reducing energy costs.

Figure: Diagram illustrating the 3D printable, modular, intensity adjustable cavitation generator developed.