THE CHALLENGE

Foam-blow molding is emerging as a more and more popular fabrication method in the polymer manufacturing industry. Polymer foams are needed in many applications including insulation, biomedical, and footwear. The important properties of a foamed polymer, such as low density or shape sustainability, are controlled by the foaming process. New and improved polymer foams can be achieved by gaining full control over the conditions at which they are produced.

OUR SOLUTION

Dr. Kiran and his team have developed a novel mold for polymer foaming that allows porous mold boundaries to expand along with the expanding polymer. The new trend is to use physical blowing agents such as carbon dioxide or nitrogen or their mixtures which are considered to be environmentally safe and benign. This tool can be used to test different blowing agents as well as adjusted for applications with different shapes. The invention can help ensure homogeneity in the final product while providing insights to physical effects of changes in the manufacturing process. The mold is of extreme value for its potential to translate the findings from laboratory evaluations to industrial scale injection mold foaming. It will allow polymer foam manufacturers to quickly bring new foams to production, giving them a major advantage over competition.

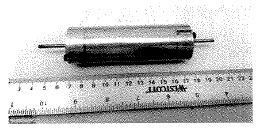

Figure: Photograph of the assembled mold