THE CHALLENGE

One of the major challenges facing the commercialization of high-performance polymers like poly(ether imide) lies in balancing their excellent thermal and mechanical properties with the need for strong resistance to harsh organic solvents—an essential requirement in industries such as coatings, electronics, and membranes. While the material is known for being easy to process and durable under heat, its tendency to dissolve or degrade in aggressive chemicals limits its use in real-world, high-demand environments. Existing technical solutions, like UV or thermal crosslinking to strengthen chemical resistance, often fall short due to inefficiencies, safety concerns, and added manufacturing costs. For businesses, this means higher production complexity, limited product lifespan, and missed opportunities in solvent-intensive markets. A reliable, scalable method to enhance solvent resistance without compromising processability or safety remains a significant unmet need, with strong commercial implications for industries seeking more robust and cost-effective materials.

OUR SOLUTION

Our solution offers a breakthrough in producing solvent-resistant poly(ether imide) films through a scalable, efficient, and safe thermal crosslinking process that transforms standard PEI into a high-performance material. By chemically modifying amine-terminated PEIs using a controlled diazotization-azidation method and inducing crosslinking through a precisely programmed heat treatment, we achieve a densely crosslinked polymer network with superior thermal stability, mechanical strength, and exceptional resistance to aggressive solvents like THF, DCM, and DMF. This innovation eliminates the limitations of traditional UV or noncovalent methods—such as poor efficiency, high processing costs, or material degradation—offering manufacturers a cost-effective and reliable way to produce durable, high-performance films. This technology opens new market opportunities in sectors demanding chemical-resistant materials, including electronics, membranes, and industrial coatings, with the added advantage of being compatible with existing manufacturing processes.

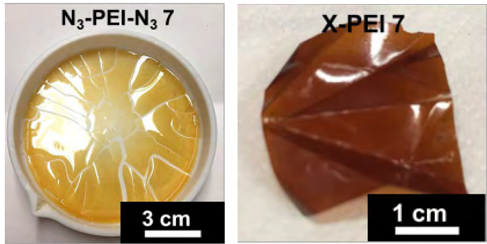

Figure: Flexibility test Before crosslinking and After crosslinking, X-PEI-7 film showed drastically improved flexibility. The film remained intact after abusive folding, stretching, and tension.

Advantages:

- Outstanding solvent resistance in harsh organic media

- Superior thermal and mechanical stability

- Simplified, cost-effective, and safe processing

- Tunable properties via controlled molecular weight and crosslinking density

Potential Application:

- Solvent-resistant protective coatings (Consumer electronics)

- Fuel cell membranes

- Filtration and gas separation membranes

- Battery separators