THE CHALLENGE

One of the biggest challenges facing the commercialization of cultivated meat is the heavy reliance on fetal bovine serum (FBS) in cell culture media—a component that is not only extremely expensive and ethically problematic, but also inconsistent due to its undefined and variable composition. FBS presents a major bottleneck to scaling production in a cost-effective and reproducible way. Technical efforts to replace FBS with serum-free or reduced-serum formulations using plant-based, microbial, or insect-derived protein hydrolysates and recombinant growth factors are promising but still face obstacles like toxicity at high concentrations, complex optimization of nutrient profiles, and batch inconsistency. These issues make it difficult to ensure predictable cell growth and quality across production runs—key requirements for meeting regulatory standards, investor expectations, and consumer trust. To unlock the full market potential of cultivated meat, we must develop media solutions that are ethically sound, scalable, affordable, and scientifically reliable.

OUR SOLUTION

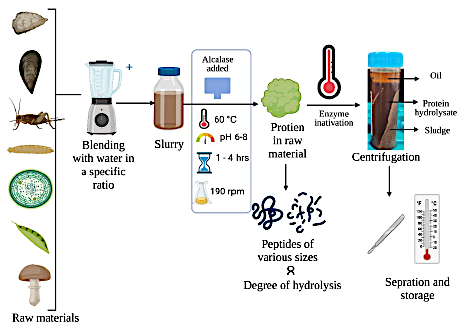

We offer a game-changing serum replacement for cell culture media, designed specifically to meet the growing commercial demands of cultivated meat production. By leveraging protein hydrolysates derived from sustainable sources like insects, algae, and fungi, we’ve developed a cost-effective and ethically sound alternative to Fetal Bovine Serum (FBS). These hydrolysates are produced using a controlled enzymatic process that ensures consistency in composition—key to reliable and scalable manufacturing. The result is a defined, reproducible formulation that supports robust cell growth across both serum-based and serum-free systems, significantly reducing production costs, ethical concerns, and variability. This innovation positions us to scale cultivated meat efficiently while meeting regulatory standards, improving margins, and appealing to ethically conscious consumers.

Figure: Overview of the process used

Advantages:

- Significant cost reduction through replacement of FBS with sustainable protein hydrolysates

- Ethical and sustainable sourcing using insect, algae, and marine-derived proteins

- Defined, reproducible composition that minimizes batch-to-batch variability

- Enhanced cell growth performance in reduced-serum and serum-free conditions

Potential Application:

- Cultivated meat and seafood production

- Biopharmaceutical and cell therapy manufacturing

- Research and diagnostic cell culture

- Commercial cell culture kits and devices