THE CHALLENGE

The growing demand for rare earth elements (REEs) in clean energy, electronics, and advanced technologies presents a major opportunity, but current extraction methods face serious limitations that hinder commercial scalability. Traditional techniques—such as surface-functionalized sorbents and solvent-based extraction—often struggle with low selectivity, poor efficiency in dilute solutions, and complex, multi-step processing, driving up operational costs and limiting throughput. These approaches also require harsh chemical conditions and frequently extract unwanted metals, complicating purification and increasing waste. For industries aiming to tap into unconventional REE sources like coal ash or industrial wastewater, there is a pressing need for cost-effective, high-capacity materials that offer tunable selectivity and robust performance across diverse conditions. Solving these technical hurdles isn’t just a scientific challenge—it’s a market-driven necessity for enabling more sustainable, efficient, and profitable REE recovery at scale.

OUR SOLUTION

We offer next-generation polymer resin designed for efficient and selective recovery of rare earth elements (REEs), even from low-concentration or complex industrial waste streams. Unlike traditional materials that only work at the surface, our resin is bulk-functionalized with phosphonate groups throughout its structure, dramatically increasing its capacity and performance. These specialized chemical groups form strong bonds with REEs—especially heavier ones—under favorable conditions, making the process both more selective and more efficient. The resin’s tunable porous architecture further enhances its ability to capture valuable metals while filtering out unwanted ones. Backed by rigorous testing and scalable synthesis, this innovation offers industries a cost-effective, high-performance alternative to conventional REE extraction methods—ideal for clean energy, electronics, and sustainable resource recovery.

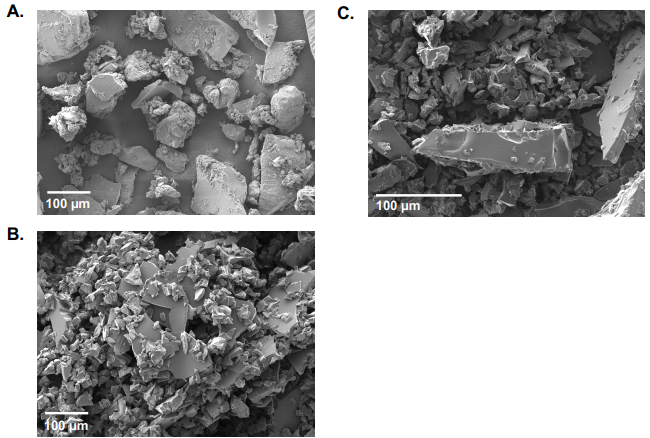

Figure: SEM images of the A. netPoly(DETA)-v-ECH, B. netPoly(DETA)-v-ECH MP, and C. netPoly(DETA)-v- 203 ECH MP after REE capture.

Advantages:

- High REE sorption capacity

- Tunable selectivity for heavier REEs through size-matched chelation

- Effective in dilute, complex matrices with strong performance at near-neutral pH

- Cost-effective, scalable synthesis from readily available chemicals

Potential Application:

- Rare earth recovery from coal ash and mining drainage

- Industrial wastewater treatment for REE extraction

- Integration into high-tech manufacturing for REE purification

- On-site microfluidic or modular extraction systems