THE CHALLENGE

The global surge in lithium demand, fueled by the expansion of battery-dependent technologies, has intensified efforts to recover lithium efficiently from low-concentration sources such as brines and produced waters. Traditional extraction methods like acid leaching and pyrolysis often face challenges related to poor selectivity, high energy consumption, and significant environmental impact. Adsorption-based methods, while offering advantages in simplicity and lower energy use, frequently struggle with limited adsorption capacities and reduced efficiency in complex matrices due to the inherent shortcomings of conventional inorganic adsorbents. Moreover, managing the surface chemistry and porosity of these materials to achieve rapid, selective adsorption and robust recyclability remains an ongoing challenge in the field.

OUR SOLUTION

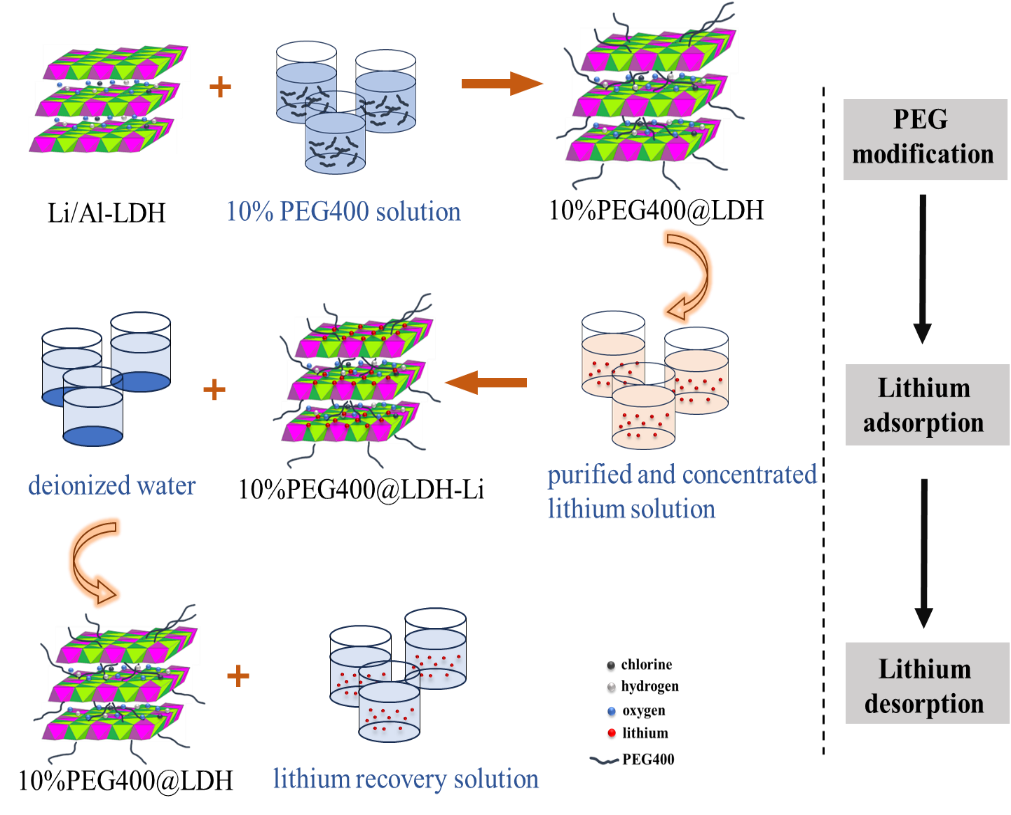

This technology utilizes advanced polymer modification of lithium/aluminum layered double hydroxide materials to enhance lithium extraction from low-concentration sources. By incorporating polymer chains either during co-precipitation or via post-synthesis mixing, polymers such as polyacrylic acid and polyethylene glycol introduce functional groups that increase surface electron density and tune the material’s porosity, surface charge, and binding kinetics. Rapid lithium adsorption equilibrium is achieved within minutes, with marked improvements in adsorption capacity and recyclability validated through extensive characterizations including X-ray diffraction, infrared spectroscopy, and density functional theory calculations. These modifications yield rapid and selective lithium adsorption with improved capacities and excellent recyclability, outperforming conventional inorganic adsorbents and earlier modifications by offering a tunable, environmentally friendly, and sustainable alternative for efficient lithium recovery.

Figure: Schematic diagram of lithium extraction process using 10%PEG400@LDH.

Advantages:

- Enhanced Lithium Adsorption Capacity

- Improved Selectivity and Rapid Kinetics

- Excellent Recyclability and Operational Stability

- Environmentally Friendly and Low Energy Consumption

- Simple and Scalable Synthesis Process

- Broad Applicability to Low-Concentration Lithium Sources

Potential Application:

- Produced water lithium extraction

- Seawater lithium recovery

- Underground brine lithium extraction

- Mineral water lithium extraction