THE CHALLENGE

The rapid growth in lithium-ion battery demand has intensified the search for efficient and sustainable lithium extraction methods from brine sources, yet conventional powder and granular adsorbents as well as evaporation and membrane-based techniques continue to face significant challenges. These traditional approaches often struggle with limited mechanical stability, suboptimal mass transfer rates, and rapid clogging or pressure drop issues in continuous-flow systems, while also exhibiting difficulties in regenerability and consistent long-term performance. Additionally, achieving a balance between high ion selectivity and fast adsorption kinetics remains problematic due to less-than-ideal pore structures and diffusion limitations, prompting researchers to explore novel material architectures that can address these shortcomings and offer more effective process scalability and operational durability for industrial lithium recovery.

OUR SOLUTION

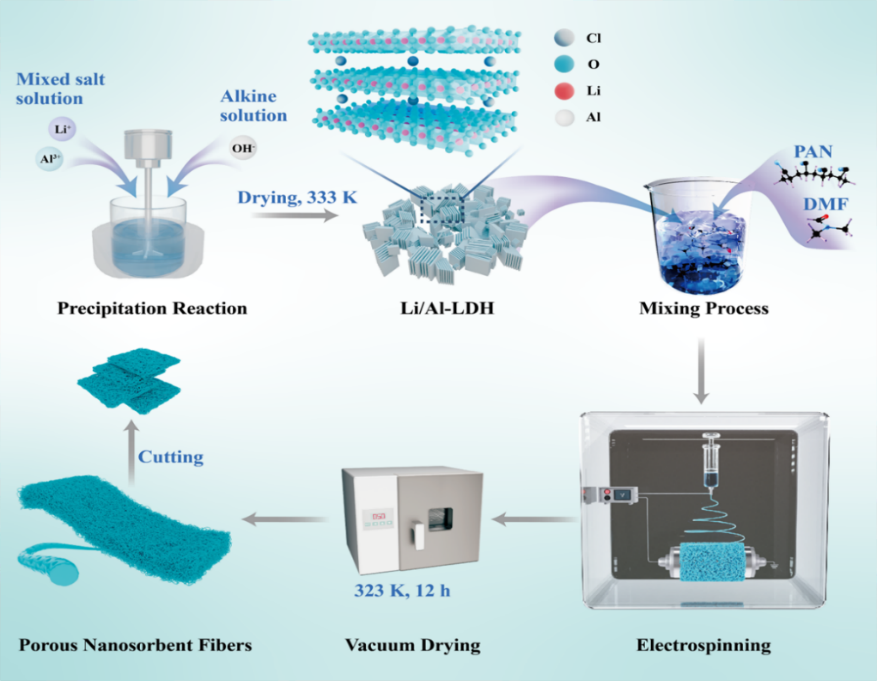

This process introduces a novel method for creating electrospun nanosorbent fibers with enhanced physicochemical properties, designed for high-efficiency lithium extraction. Central to this innovation is the first-ever use of a polyacrylonitrile /dimethylformamide matrix to fabricate fibrous lithium/aluminum layered double hydroxide (Li/Al-LDH) adsorbents. These fibers boast an average diameter of approximately 546 nm and exhibit impressive mechanical strength, rapid wetting kinetics, and a hierarchical porous architecture that includes both micropores and mesopores. Characterization techniques—such as SEM, XRD, FTIR, and XPS—and DFT simulations confirm strong hydrogen bonding between the PAN cyano groups and water molecules in the layered double hydroxide, enhancing lithium adsorption capacity and selectivity while ensuring stability over multiple adsorption–desorption cycles. Unlike traditional powder or granular forms of Li/Al-LDH adsorbents, this novel fiber-based approach improves fluid flow, reduces diffusion distances, and offers stable cyclic performance, thereby providing a more efficient and sustainable method for industrial lithium recovery.

Figure: Schematic diagram of the Li-PNFs preparation procedures.

Advantages:

- Enhanced Mechanical Integrity

- Improved Mass Transfer and Adsorption Kinetics

- Superior Hydrophilicity and Wetting Performance

- Robust Cyclic Stability and Reusability

- Robust Cyclic Stability

Potential Application:

- Industrial lithium extraction

- Salt Lake lithium recovery

- Geothermal brine extraction

- Lithium battery recycling