THE CHALLENGE

The growing use of lithium-ion batteries has intensified the need to efficiently extract valuable metals from spent batteries, yet existing recycling methods face major challenges. Traditional techniques such as pyrometallurgy require high energy inputs and often produce significant emissions, while conventional hydrometallurgical processes, though less energy-intensive, typically rely on strong inorganic acids and unstable or environmentally harmful reductants, leading to high chemical consumption and potential pollution. Efforts to adopt greener organic reductants and advanced heating methods, like microwave-assisted leaching, have shown promise but still struggle with achieving complete metal recovery, precise control of reaction parameters, and maintaining robust kinetics, which limits their scalability and economic viability.

OUR SOLUTION

This process employs a microwave-assisted hydrometallurgical technique to process spent lithium-ion battery black mass, using a low-concentration sulfuric acid solution combined with organic reductants such as citric acid or biomass. Relatively mild reaction conditions including low temperatures and short reaction times result in near-complete recovery of valuable metals including lithium, manganese, cobalt, and nickel. Biomass waste and citric acid offer cost-effective and sustainable reducing agents that efficiently reduce metal ions under microwave irradiation, thereby overcoming challenges of instability and environmental concerns associated with traditional inorganic reductants and high-acid systems.

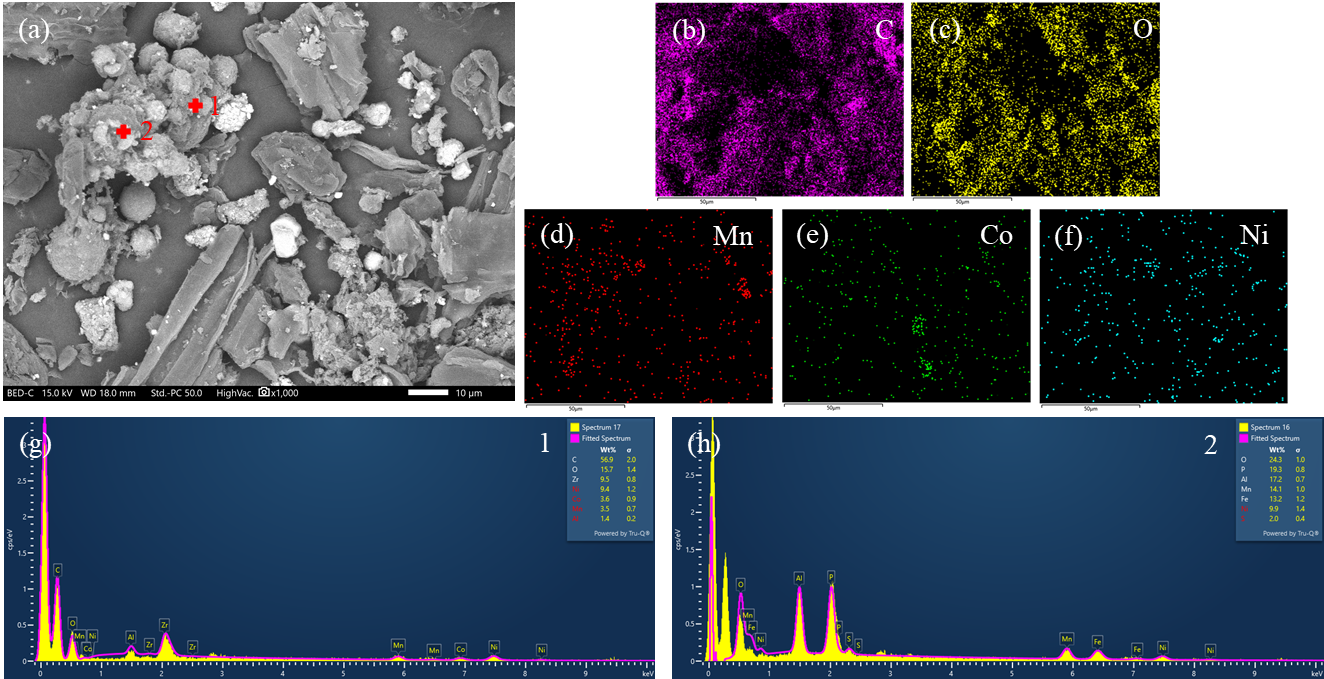

Figure: SEM image of leaching residue treated under 120ºC microwave-assisted leaching process (a) as well as corresponding EDS mapping (b)-(f) and EDS analysis (g)-(h).

Advantages:

- High Metal Recovery Efficiency.

- Sustainable and Eco-Friendly Reducing Agents

- Rapid Processing through Microwave Assistance

- Reduced Chemical Consumption and Lower Energy Use

- Versatility in Metal Recovery

Potential Application:

- Battery Recycling Operations

- Closed-Loop Battery Manufacturing