THE CHALLENGE

Developing advanced contactless manipulation technologies lies in creating a solution that is not only technically effective but also scalable, affordable, and easy to integrate into real-world biomedical and chemical workflows. Current methods—like optical tweezers, magnetic actuators, and traditional acoustic systems—are either too bulky, costly, or limited in precision, making them impractical for widespread commercial use. These approaches often require complex hardware, risk damaging sensitive samples, and struggle to adapt to the wide variety of object sizes and fluid environments found in diagnostics, drug discovery, and microfluidics. The market demands a compact, programmable, and biocompatible system that can perform high-resolution, non-contact manipulation on liquid surfaces without the need for expensive infrastructure or specialized operation—opening up opportunities for automation, miniaturization, and broader adoption in lab-on-a-chip platforms and point-of-care devices.

OUR SOLUTION

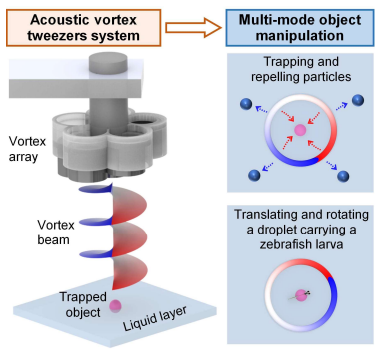

We offer a compact, cost-effective, and portable system for contactless manipulation of small objects on liquid surfaces—addressing key market demands in biomedical, chemical, and microfluidic applications. Unlike bulky or expensive traditional systems, this battery-powered device uses a unique arrangement of just five ultrasound transducers to generate a controlled acoustic vortex beam, enabling precise, programmable actions such as trapping, moving, spinning, or merging droplets without any physical contact. The system’s motion is guided by simple G-code programming and a high-resolution positioning stage, making it easy to integrate into automated workflows. By combining advanced wavefield modeling with real-time control, our technology enables safer, cleaner, and more flexible manipulation—ideal for labs and diagnostic settings looking to minimize contamination, reduce infrastructure costs, and boost operational efficiency.

Figure: Mechanism of an acoustic vortex end effector-based tweezers system for contactless and multifunctional object surfing

Advantages:

- Low-cost and portable design using off-the-shelf components (~$60)

- High-precision control with sub-millimeter resolution (0.05–0.1 mm)

- Programmable multi-mode manipulation via G-code (trapping, spinning, translating)

- Contactless and biocompatible operation minimizing contamination risks

Potential Application:

- Automated biological sample handling

- Contactless droplet merging and mixing

- Precision object sorting in lab-on-chip systems

- Microfluidic research and development