THE CHALLENGE

The growing market for wearable tech, soft robotics, and flexible displays is driving urgent demand for printable conductive materials that work reliably on bendable or stretchable surfaces—without the need for high heat or complex processing. However, current solutions force businesses into tough trade-offs: silver and copper nanoparticle inks offer great conductivity but require high-temperature sintering, making them incompatible with soft plastics; carbon-based inks are easier to print but too resistive for real-world use; and liquid metals, while ultra-flexible, are hard to control, stick poorly to surfaces, and degrade over time. These technical limitations translate into business risks—higher manufacturing costs, limited scalability, product reliability issues, and reduced design flexibility. Companies need a one-stop, scalable material solution that delivers high conductivity, strong adhesion, and low-temperature processability without compromising on mechanical durability or print precision.

OUR SOLUTION

We offer a next-generation, printable liquid metal paste that bridges the gap between high-performance engineering and scalable manufacturing for flexible electronics. By dispersing copper particles into a gallium–indium alloy, we’ve developed a thixotropic, semi-solid material that can be easily patterned using standard printing techniques—no high heat or specialized equipment required. Unlike traditional inks or solders, this paste offers built-in adhesion and cures at low temperatures, enabling direct bonding of components on soft, stretchable, or heat-sensitive surfaces. It delivers high electrical and thermal conductivity, while its customizable composition supports a range of use cases—from wearable sensors to 3D-printed circuits. The business advantage is clear: reduced assembly steps, lower processing costs, and expanded design freedom without sacrificing durability or performance.

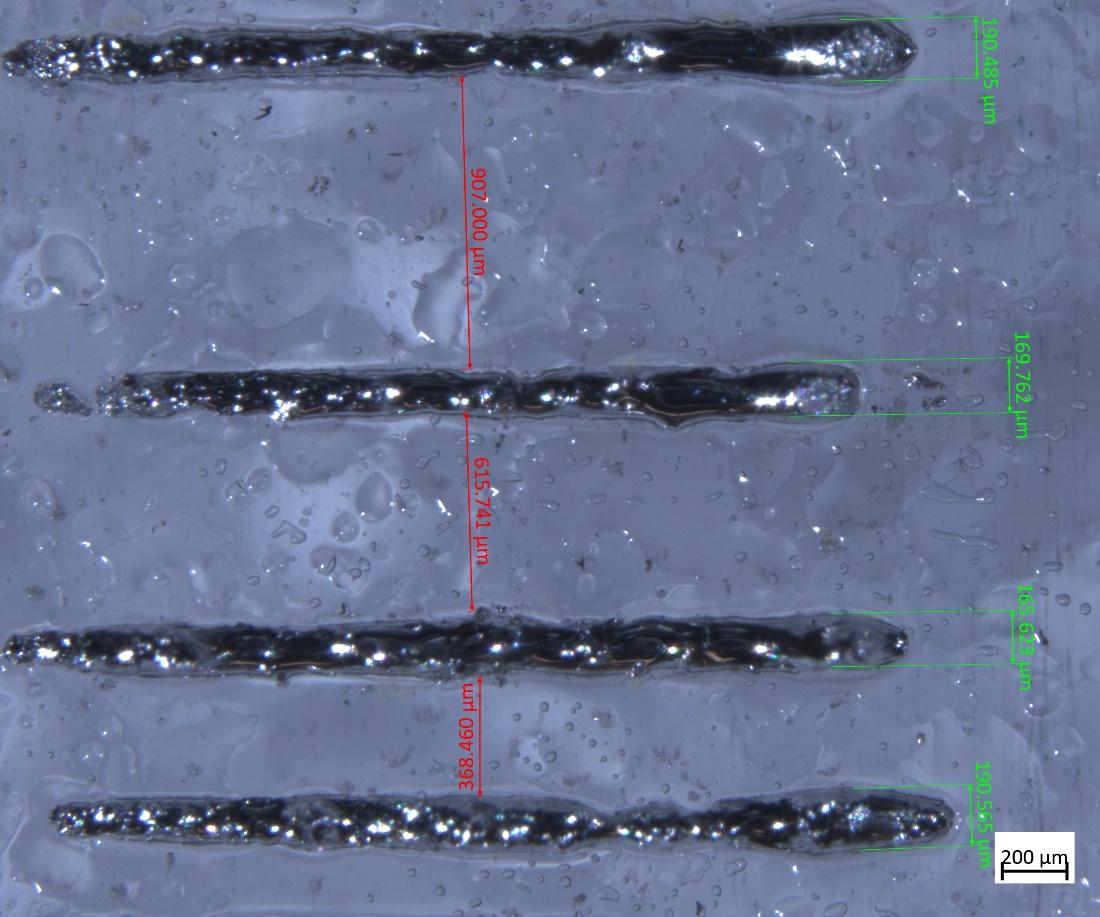

Figure: Required paste applied on the surface in the required pattern using a stencil mask

Advantages:

- Low-temperature, sinter-free curing (≤100 °C)

- Integrated adhesion and conductivity

- Tunable rheology for multiple printing methods

- High flexibility and stretchability (>100% strain)

Potential Application:

- Flexible and stretchable electronic sensors

- Wearable electronic devices

- Soft robotics interconnects

- Additive manufacturing of conductive circuits