THE CHALLENGE

Underwater manipulation is essential for tasks like marine research, infrastructure repair, environmental monitoring, and resource extraction—where precise, reliable interaction with submerged objects is critical yet technically challenging. Currently, there is a lack of reliable, efficient, and adaptable gripping technologies that can perform in dynamic, real-world conditions. Existing solutions such as suction cups, rigid claws, and static adhesives struggle with water interference, surface irregularities, and object misalignment, leading to frequent slippage, slow operation, and equipment damage. These systems often require bulky hardware, high energy consumption, and manual activation, making them unsuitable for commercial applications where speed, precision, and automation are essential. Moreover, the absence of embedded sensors or real-time feedback prevents intelligent control, limiting their use in industries like marine robotics, offshore maintenance, and underwater inspection. There is a growing market need for smart, soft gripping technologies that can conform to various shapes, sense contact conditions, and switch rapidly between strong adhesion and release—enabling safer, faster, and more cost-effective underwater operations.

OUR SOLUTION

Our solution is a smart, wearable underwater gripping system that combines soft, octopus-inspired adhesive pads with real-time sensing and autonomous control, offering a breakthrough in underwater handling and robotics. Each adhesive unit switches rapidly between strong grip and easy release—over 450× strength modulation in under 50 milliseconds—using compact pneumatic control. Integrated micro-LIDAR sensors and onboard microcontrollers allow the system to detect nearby objects and respond automatically, enabling fast, precise, and gentle manipulation of a wide range of shapes, even on rough or inclined surfaces. Built into a flexible glove-like platform, the system routes all electronics and pneumatics through a lightweight, user-friendly design, eliminating bulky hardware. This technology provides a high-performance, scalable solution for industries like marine inspection, aquaculture, offshore maintenance, and underwater research, where current gripping tools are too slow, rigid, or unreliable for real-world environments.

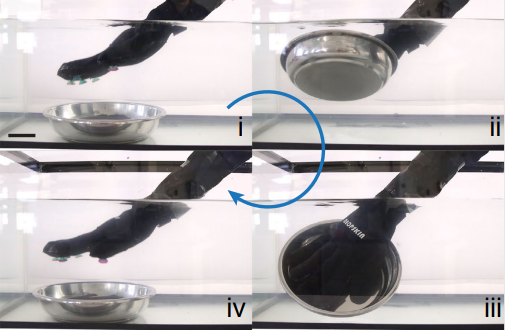

Figure: Demonstration of multiple adhesives and sensors on the adhesive glove to grip, lift, and release a large metal bowl in water

Advantages:

- Ultra-fast adhesion switching

- Autonomous control via integrated micro-LIDAR and onboard microcontroller

- Reliable grip on irregular surfaces with tunable stalk geometry

- Compact, wearable design for multi-site, untethered underwater use

Potential Application:

- Underwater robotic and inspection grippers

- Aquaculture handling and harvesting tools

- Diver-assist sensorized gloves

- Wet manufacturing and assembly line grippers