THE CHALLENGE

Problem with current extrusion-based additive manufacturing lies in its heavy dependence on standard round nozzles, which limit the ability to control the shape of material strands as they are deposited. This restriction forces companies to rely on workarounds such as complex software strategies, fine-tuned printing parameters, or costly post-processing steps to achieve functional features like textures for improved grip, moisture management, or specialized surface textures. These extra steps not only slow down production but also increase manufacturing costs and reduce scalability, making it difficult for businesses to fully leverage 3D printing for high-value applications in sectors like textiles, healthcare, and advanced engineering where customized material performance is essential.

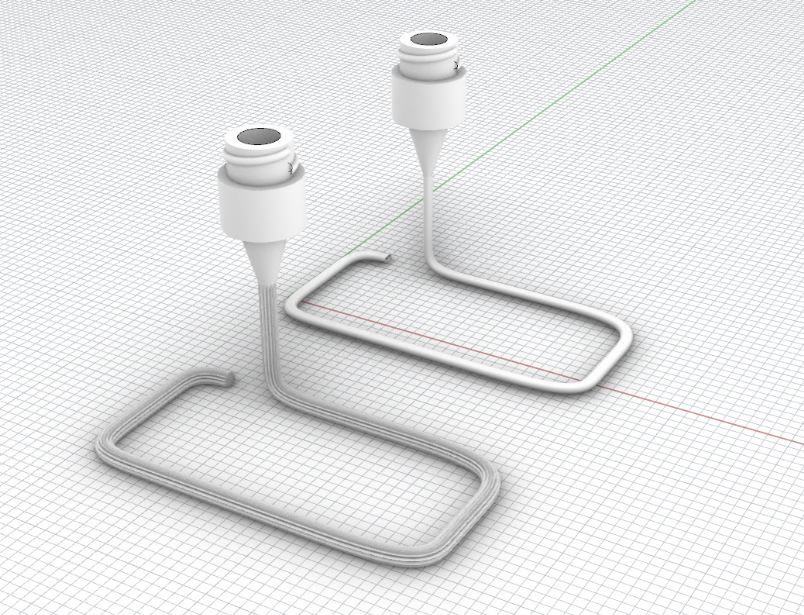

OUR SOLUTION

This technology features a series of 3D printer nozzles with custom-shaped tips or orifices, including a dynamic shape adjustable nozzle tip, designed to precisely control the cross-sectional geometry of extruded materials during the 3D printing process which are compatible with a variety of materials, including molten plastics, ceramics, and biomaterial slurries such as paper or hemp pulp. By altering the shape of the nozzle’s exit, users can tailor the deposited material’s section for specific functional and visual outcomes. What sets this technology apart is its ability to dramatically expand the functional and design possibilities of additive manufacturing without requiring significant changes to existing 3D printers. The solution is both cost-effective and versatile, as it can be marketed as an add-on accessory or integrated into new printer designs, making advanced material customization accessible to DIY enthusiasts, professionals, and industrial users alike. This approach provides a straightforward yet powerful way to unlock new applications and efficiencies in 3D printing, setting it apart from conventional additive manufacturing tools.

Figure: Different outcomes from different nozzles.

Advantages:

- Precise control of filament cross-sections

- Customizable surface textures and aesthetics

- Enhanced functionality for applications like moisture management

- Broad compatibility with materials and printer types

Potential Application:

- Grip-enhanced tools and components

- Moisture-wicking and water-harvesting textiles

- Ceramic, concrete and construction parts with tailored surfaces for architectural applications: evaporative cooling.

- Custom aesthetic and decorative products