THE CHALLENGE

Unmanned Aerial Systems (UAS), or drones, are critical for a wide range of applications from data acquisition to delivery. Due to prioritization of high production volumes, current drone manufacturing methods utilize injection molded parts, require human operator inspection, and are postured to only produce one-size-fits-all drone designs. Traditional manufacturing methodologies delay design changes intended to optimize drone performance with respect to jobs or environments.

OUR SOLUTION

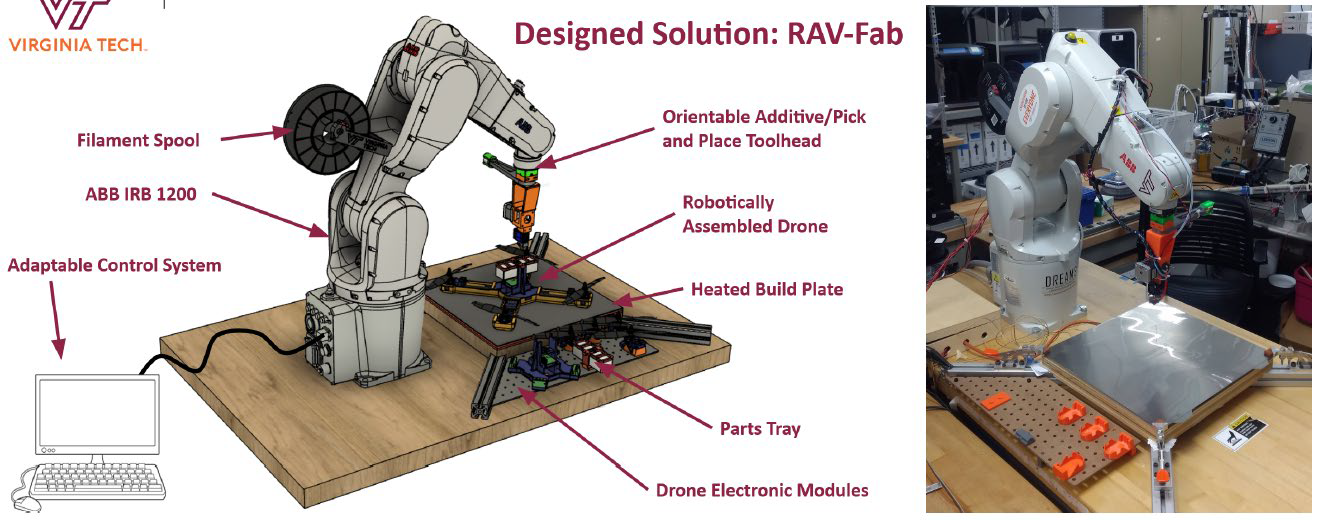

The VT DREAMS lab has developed a robotic, multi-process work cell to autonomously fabricate UAS tailored for immediate application needs, called Robotic Aerial Vehicle Fabricator. The work cell consists of a robotic arm with a tool changer to enable material extrusion additive manufacturing, and pick and place operations. Additionally, the team has designed a modular drone electronics infrastructure that accommodates varying chassis designs, battery sizes, rotor sizes, and more. This capability allows system users to modulate key metrics such as drone flight time, maneuverability, weight, and size. In one completely autonomous system, the UAS bodies can be printed, have functional hardware embedded, and fly out of the workcell at cycle finish.

Figure: Entire work cell with robotic arm, electronics tray, additive manufacturing/pick and place tools, build substrate, etc.