THE CHALLENGE

Traditional composite processing methods such as wet layup and pultrusion struggle to create small, detailed shapes with properly aligned carbon fibers. While 3D printing with short carbon fibers improves strength slightly, the chopped fibers limit their full potential. Continuous carbon fiber 3D printing works well for simple, flat printing (XY-plane), but multi-axis printing still faces major challenges—the bulky printing tool often collides with the part, it can’t cut and refeed the fiber to enable complex toolpaths, and there’s no real-time control over the fiber-to-plastic ratio. Solving these issues is key to making stronger, more efficient carbon fiber 3D-printed parts.

OUR SOLUTION

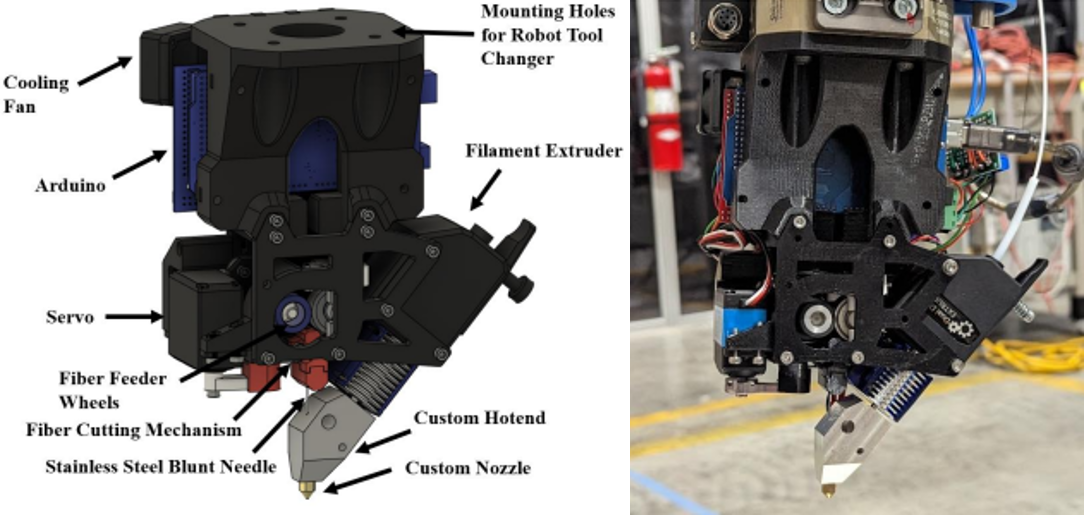

This advanced 3D printing tool enables multi-axis deposition of continuous carbon fiber reinforced with thermoplastic polymer, creating stronger and lighter parts with optimized fiber alignment. It features a servo-controlled cutting and refeeding system, allowing fiber cutting/refeeding and precise fiber placement along complex 3D toolpaths, thus overcoming the limitations of traditional layer-by-layer printing. A fiber alignment system ensures consistent fiber tension, while a unique embedded fiber insertion tool improves bonding between the fiber and polymer. Its compact design reduces its collision zone, making it well-suited for robotic multi-axis and conformal printing. With real-time control over the fiber-to-polymer ratio, this technology enhances mechanical performance, making it ideal for fabricating printed parts for aerospace, automotive, and other high-performance applications.

Figure: CAD model and assembly of the multi-axis MEX CCFR deposition tool

Advantages:

- Multi-Axis Deposition Capability

- Precise Fiber Cutting and Refeeding Mechanism

- Live Control of Fiber-to-Polymer Ratio

- Minimized Collision Volume for Complex Paths

- Enhanced Mechanical Properties via Optimal Fiber Alignment

Potential Application:

- Aerospace, Automotive and Marine (High-Performance Transportation) Components

- Customized high-strength prototypes