THE CHALLENGE

The major challenge in wearable SERS (Surface-Enhanced Raman Spectroscopy) sensors lies in bridging the gap between cutting-edge lab technology and real-world usability. While SERS offers powerful, label-free chemical detection at the molecular level, current fabrication methods rely on expensive clean-room processes, rigid substrates, and delicate nanoparticle assemblies that don’t hold up under everyday wear-and-tear—like bending, washing, or exposure to sweat and other fluids. These limitations not only drive-up production costs but also make the sensors unreliable and essentially single-use, which is impractical for scalable, low-cost applications such as continuous health monitoring, environmental diagnostics, or smart bandages. For widespread adoption, the industry needs a flexible, durable, and regenerable SERS platform that can be mass-produced using roll-to-roll techniques, deliver consistent signal quality, and withstand the physical and chemical challenges of real-life deployment—all without breaking the bank.

OUR SOLUTION

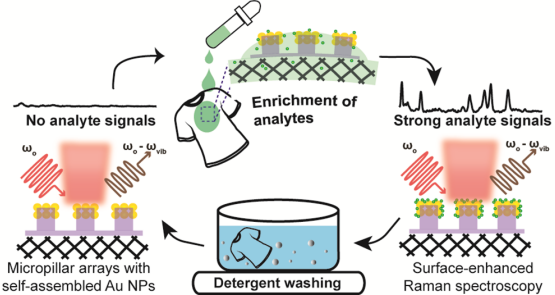

We offer a scalable, cost-effective approach to producing flexible, reusable SERS sensors by combining a clean-room–free fabrication method with robust performance on real-world surfaces. Using a unique process that self-assembles gold nanoparticles in microscale wells and embeds them into a UV-cured polymer layer, we create uniform plasmonic hotspots that are transferred onto flexible materials like textiles, membranes, and PET films. A quick plasma etching step fine-tunes the sensor’s sensitivity, while strong nanoparticle bonding ensures durability under bending, stretching, and repeated washing. This enables high-performance chemical detection—even at very low concentrations—without degradation, making it ideal for applications like smart bandages, wearable health monitors, and environmental diagnostics. By supporting roll-to-roll manufacturing and easy regeneration through simple detergent washing, our platform solves key industry barriers to commercialization, including cost, reusability, and reliability.

Figure: Overview of the process

Advantages:

- Washable and reusable without performance loss

- Uniform hotspot distribution for consistent sensing

- Strong nanoparticle–substrate adhesion on flexible materials

- Scalable, cost-effective, clean-room–free fabrication

Potential Application:

- Wound monitoring bandages

- Wearable health monitoring textiles

- Food safety sensing packaging

- Chemical threat detection wearables