THE CHALLENGE

A major problem posed by the pharmaceutical industry is giving effective dosages while not giving excessive amounts of a particular drug. An estimated 80% of side effects in humans and animals are a direct result of inaccurate dosing because varying weights in patients. Additive manufacturing has emerged as a very promising method to provide patients with customizable, rabidly produced tablets while reducing the probability of side-effects. It is a new field and thus requires significant research and effort to optimize the processes implemented.

OUR SOLUTION

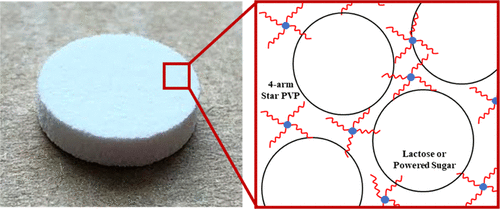

Timothy Long and his team have developed a method for manufacturing personalized dosage tablets with different polymer architectures. They used linear, 4-arm star, and graft polyvinyl pyrrolidone as polymeric binders for the additive manufacturing process. These methods open the door for a wide range of polymer architectures to be used in binder formulations to achieve a stronger printed tablet for personalized dosage medicine. With further investigation, the development of additive manufacturing of personalized dosage pharmaceuticals has the potential to revolutionize manufacturing of oral tablets.

Figure: A personalized tablet created using these new additive manufacturing techniques